Ground Foundation Request:

The ground is better to be cement self-leveling ground or ceramic tiles ground, wood floor ground. The surface of the ground need to be smooth, press polished, dry, no overmuch pores or cracks, no hollowing or bulge, no damage, no sand and keep clean.

Flooring Installation Attentions:

Generally, the air temperature for installation shall not be lower than 15℃. When the flooring material is thick and hard,the temperature should be higher correspondingly. The preference temperature should be based on the standard that the flooring material can naturally expend and be easily cut.

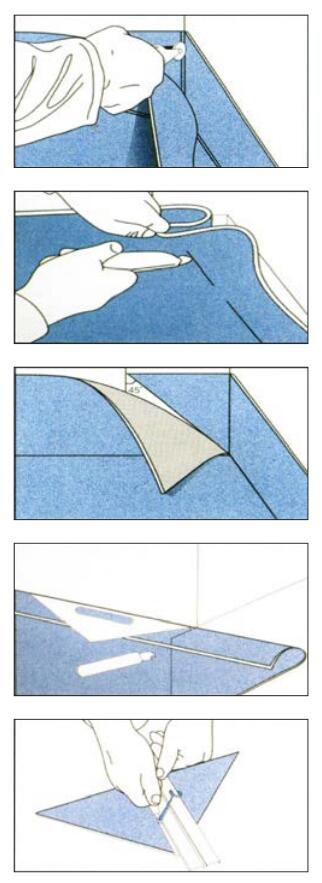

Before installing, please measure the ground dimension to get an idea of layout of the flooring roll, and please also measure the length of flooring roll to avoid that there is seam near the door.

After the flooring rolls are spread out well on the ground,brush glue and deburr on both edge of the joint. Then weld the joint and equate the welding line.

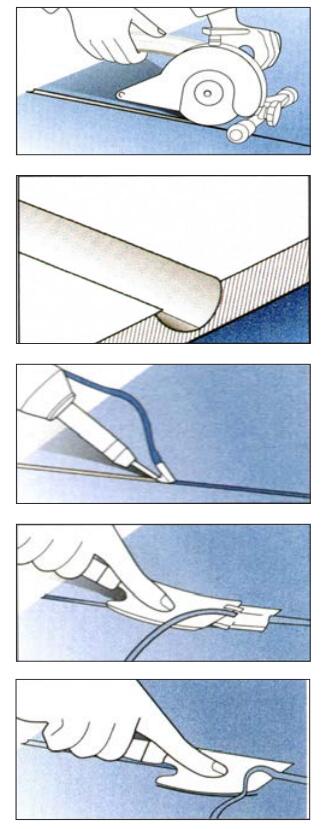

Slotting with grooving machine: In order to make the welding firm and strong, the slotting depth must be less than the thickness of flooring roll. In addition, the dust and flooring chip in the slot must be swept out before welding.

2 Installation Procedure and Method:

To make a profession court, a good construction site, a well trained installation team and qualified installation equipment are all necessary, all of them are indispensable:

1. Good construction site: please avoid cross-construction, as PVC flooring installation is the last procedure. Please don't rush in one moment, otherwise there will be damage of the working surface and flooring material surface.

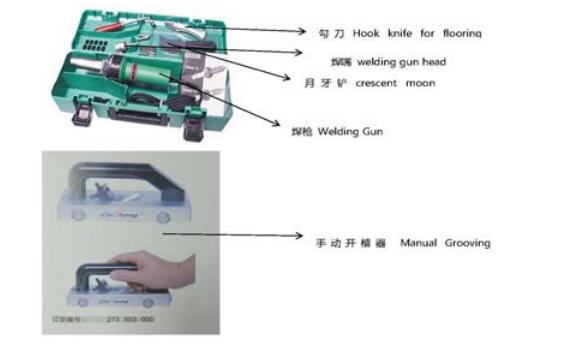

2. A well trained installation team and good installation equipment is very necessary. With this, the final installation effect can be ideally. Following are some necessary installation equipment.

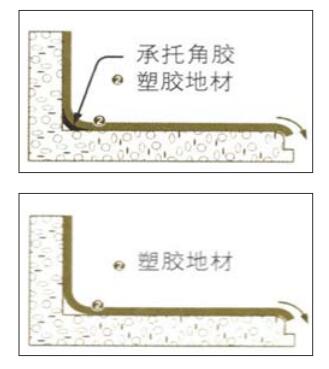

3 Fixed installation- Full glue adhesion: ( suit for concrete ground)

1. Lay out the flooring rolls and splicing each roll well together on the ground, then roll up one side of the roll.

2. Clean the ground and the back of flooring rolls

3. Scrape the glue evenly on the ground with a scraping board;

4. Glue one side then the other side

5. Push and press the flooring on the surface with soft wood to make the flooring surface smooth and exclude the air between the flooring and ground.

6. The extra glue on the flooring surface must be clean up in time.For every installation method, the grooving, welding and court line drawing procedure must be proceeded after the glue is clotted.

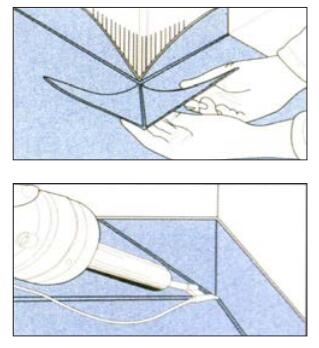

Grooving Procedure:

Grooving procedure must be proceeded after the glue totally clotted. Use a professional grooving machine, grooving along the seam. To make the floor welding firm and steady, the grooving depth must be smaller than the flooring thickness. The advised grooving depth is 2/3 of the flooring thickness. At the end of the joint where the groover can't reach, pls use manual groover to slot with same depth and width.

4 Welding Procedure:

Set the temperature of the welding gun at 800 ℃ around. Melt the welding wire with even welding speed and push the welding wire to the slot. When the welding wire is half cooling, even out the bulge part of the welding wire with a welding wire equating machine or crescent shovel.

Maintenance and Clean:

The PVC surface has rejection ability for outside contamination.If it is dirty, it can be cleaned up easily with a mop. If it is too dirty,it can be cleaned with water and neutral cleaning agent.Maintenance and cleaning cost are cheap.

Tel:0086-312-6381088

Fax:0086-312-6382788

Email:ada@juhengcn.cn

CopyRight © 2018 Baoding Juheng Plastic Manufacturing Co., Ltd. All Rights Reserved. ICP备案:冀ICP备16027403号-1 Technical Support: Dian Sou Background login